Luoyang INNO Bearing Co., Ltd.: Excellent choice for large tapered roller bearings

In the huge system of industrial machinery, bearings are like the heart of precision operation, and large tapered roller bearings are responsible for a key mission in many heavy equipment. Luoyang INNO Bearing Co., Ltd., as a leader in the industry, has demonstrated extraordinary strength and professional standards in the production and trade of large tapered roller bearings.

The unique charm of large tapered roller bearings

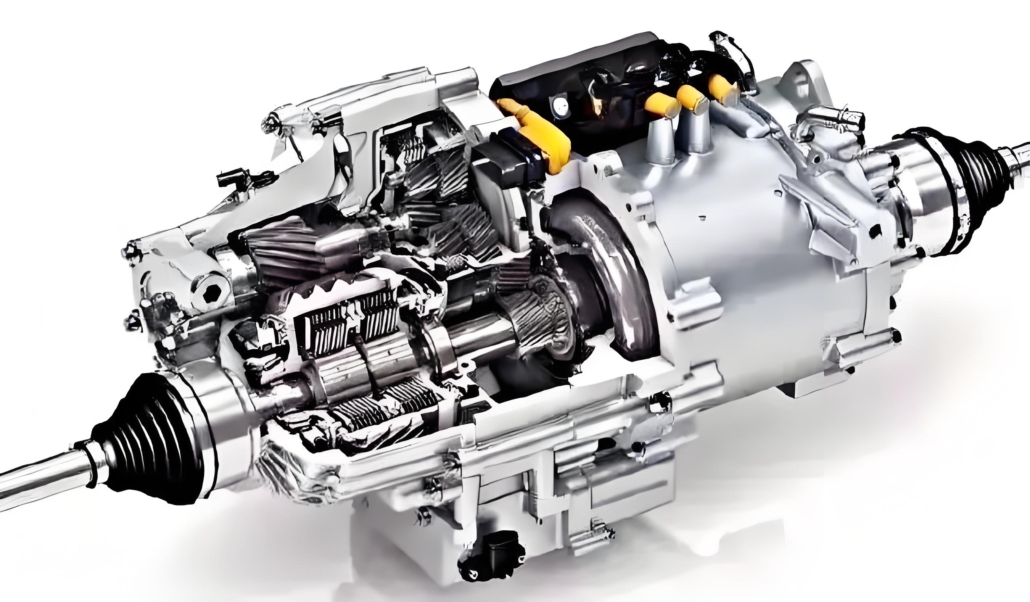

Large tapered roller bearings are unique in design. The raceway surfaces of the inner and outer rings and the cone apex of the rollers are cleverly converged at a point on the central axis of the bearing. The truncated cone rollers are precisely assembled as core rolling elements and carefully guided by the large flange of the inner ring. This ingenious design gives it a strong load-bearing capacity, which can not only withstand heavy radial loads, but also cope with unidirectional axial loads. The axial force generated when the load acts on the bearing is usually resolved by using two bearings opposite to each other or using double-row bearings. Moreover, thanks to its separable structural design, the inner and outer rings can be disassembled separately, which greatly facilitates the installation, maintenance and overhaul of the equipment.

According to the difference in contact angle, large tapered roller bearings can be divided into ordinary tapered angle, medium tapered angle, and large tapered angle bearings; according to the number of roller rows, they can be divided into double-row and four-row tapered roller bearings. In terms of the selection of cages, steel plate stamping cages are generally used, while large-size tapered roller bearings will use pin-type cages to ensure that the bearings can still operate stably and efficiently under harsh working conditions such as high loads and high speeds.

Wide and diverse application areas

Large tapered roller bearings play an indispensable role in many industries due to their excellent performance. In the field of metal cutting machine tools, it ensures the precise rotation of the machine tool spindle, providing a solid guarantee for high-precision parts processing; converters, casting equipment and rolling mills in steel processing equipment can withstand huge pressure and impact force under the support of large tapered roller bearings, and achieve continuous and stable production operations; mechanical transmission equipment relies on it to efficiently transmit power and ensure the smooth operation of the transmission system; heavy equipment such as papermaking machinery, cement machinery, mills, mining machinery, engineering machinery and vibration machinery are also inseparable from the reliable operation of large tapered roller bearings under complex working conditions such as heavy loads and impacts. In addition, in the fields of environmental protection equipment, wind power generation equipment, ships, antennas and radars, textile machinery, packaging machinery, etc., large tapered roller bearings are also very useful, injecting strong impetus into the development of various industries.

The profound heritage of Luoyang INNO Bearing Co., Ltd.

Since its establishment in 2020, Luoyang INNO Bearing Co., Ltd. has been working hard in the field of bearings and has quickly emerged. The company is located in Jianxi District, Luoyang City, Henan Province, where rich bearing industry resources and technical talents are gathered. Relying on the technology, talents, management and brand advantages of Ruihuan Bearing of Luoyang Bearing Group, INNO Bearing actively carries out large-scale bearing production and maintenance business. After years of unremitting efforts, it has established a solid cooperative relationship with more than 300 bearing manufacturers and built a huge and complete industrial ecological chain.

The company has been focusing on the bearing field for 25 years and has a full range of bearing research and development and manufacturing capabilities. Its products cover all key links in the bearing industry chain. There are more than 3,000 bearing products with specifications below 3500MM developed and produced, among which large tapered roller bearings are one of the company’s advantageous products. INNO Bearing always adheres to strict quality standards. All kinds of products produced meet national standards and industry standards, and the product accuracy can reach P0 (G), P6 (E), and P5 (D). The company adopts computer optimization-aided design to ensure that the product performance is in the best state, and uses testing instruments certified by the national first-level measurement unit to ensure the accuracy of product size transmission.

Service-oriented business philosophy

In terms of service, Luoyang INNO Bearing Co., Ltd. provides customers with comprehensive solutions from product training to sales support to engineering resources. The company has a stock of 1 million bearings and can achieve fast delivery within 7 days, which greatly meets the urgent needs of customers. In addition, INNO Bearing can also provide customers with repair services for imported bearings and extra-large bearings, effectively reducing customers’ procurement costs. This thoughtful service has won high recognition and praise from many customers.

With superb technology, strict management and high-quality services, Luoyang INNO Bearing Co., Ltd. has established a good reputation in the industry. Its products are not only popular in the domestic market, but also exported to many countries and regions around the world. Whether in traditional industrial fields such as metallurgy, cement, and mining, or in emerging industries such as wind power generation, Luoyang INNO Bearing Co., Ltd.’s large tapered roller bearings create huge value for customers with their excellent quality and performance.

If you are looking for high-quality large tapered roller bearing solutions, Luoyang INNO Bearing Co., Ltd. is undoubtedly your ideal partner. We will serve you wholeheartedly and help your business flourish with professional products and high-quality services.